Porducts

We provide a widely variety of solutions for your needs, whether you need the standard materials or special design.Factory Supply Low Headroom Electric Wire Rope Hoist

Long Description

Key Features :

1. Low Headroom Design: One of the outstanding features of the LMD1 hoist is its low headroom design, allowing it to operate efficiently in areas with limited overhead space. This design is crucial in facilities where maximizing vertical space is essential.

2. High-Strength Materials:The hoist is constructed with high-strength alloy steel, ensuring outstanding durability and reliability under heavy loads and frequent use.

3. Versatility: This electric wire rope hoist is highly versatile and adaptable to various lifting tasks. It is commonly used in industries such as construction, manufacturing, logistics, warehousing, and maritime, among others.

4. Safety Features:Safety is a top priority. The LMD1 hoist is equipped with various safety features, including limit switches and emergency stop buttons, ensuring safe and controlled lifting operations.

5. Efficiency: The hoist boasts powerful motors and drive systems, providing fast and efficient lifting. This efficiency contributes to increased productivity in various industrial environments.

6. Customization: To meet specific requirements for different applications, the LMD1 hoist offers a range of specifications and sizes. This customization ensures it can handle a variety of lifting tasks.

7. Ease of Maintenance: The hoist is designed for simplicity, making it easy to maintain and repair, minimizing downtime and reducing overall operating costs.

Detail Display

Detail

1.WIRE ROPE:

Tensile strength up to2160M Pa ,antiseptic surface, phosphating treatment;

2.HOOK

T-grade high strengthforging, DIN forging;

3.MOTOR:

Sufficient solid coppermotor, the service life can reach1 million timesHigh protection level. Support double speed;

4.REDUCER

High-precision geargrinding technology,complete types and wideapplications;

| Specification | Double Speed Electric Hoist | |||||||||

| Lifting Weight(t) |

0.25 |

0.5 |

1 |

2 |

3 |

5 |

10 |

16 |

20 |

|

| Hoisting height(m) | 3, 6, 9 | 3, 6, 9 | 6, 9, 12, | 6, 9, 12, | 6, 9, 12, | 6, 9, 12, | 6, 9, 12, | 9, 12, 18 | 9, 12, 18 | |

| 18, 24, 30 | 18, 24, 30 | 18, 24, 30 | 18, 24, 30 | 18, 24, 30 | ||||||

| Hoistling speed(m/min) |

8 |

0.8/8 | 0.8/8 | 0.8/88 | 0.8/8 | 0.8/8 | 0.7/78 | 0.35/3.5 |

4 |

|

| Travel speed(m/min) |

20 |

20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 |

20 |

20 |

|

| Steel wire | Dia(mm) |

3.6 |

4.8 |

7.7 |

11 |

13 |

15 |

15 |

17.5 |

19.5 |

| rope | Specification | 6*19 | 6*37+1 | 6*37+1 | 6*37+1 | 6*37+1 | 6*37+1 | 6*37+1 | 6*37+1 | 6*37+1 |

| Track | 16-22b | 16-28b | 16-28b | 20a-32c | 20a-32c | 25a-45c | 32b-63c | 45b-63c | 56b-63c | |

| Type | ZD112-4 | ZD121-4 | ZD122-4 | ZD131-4 | ZD132-4 | ZD141-4 | ZD151-4 | ZD151-4 | ZD152-4 | |

| ZDS0.2/0.8 | ZDS0.2/1.5 | ZDS0.2/3.0 | ZDS0.2/4.5 | ZDS0.2/7.5 | ZDS0.2/13 | ZDS0.2/13 | ||||

| Hoisting | Power(kw) |

0.4 |

0.8;0.2/0.8 | 1.5;0.2/1.5 | 3.0;0.4/3.0 | 4.5;0.4/4.5 | 7.5;0.8/7.5 | 13;1.5/13 | 13;1.5/13 |

18.5 |

| motor |

|

|

||||||||

| Rotation |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

|

| speed (r/min) |

|

|

|

|

|

|

|

|

|

|

| Current(A) |

1.25 |

2.4,0.72/4.3 | 4.3,0.72/4.3 | 7.6,1.25/7.6 | 11,2.4/11 | 18,2.4/18 | 30,4.3/30 | 30,4.3/30 |

41.7 |

|

| Type | ZDY110-4 | ZDY111-4 | ZDY111-4 | ZDY112-4 | ZDY112-4 | ZDY121-4 | ZDY121-4 | ZDY121-4 | ZDY121-4 | |

| Power(kw) |

0.06 |

0.2 |

0.2 |

0.4 |

0.4 |

0.8 |

0.8*2 | 0.8*2 | 0.8*2 | |

| Travel | Rotation |

1400 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

| motor | speed (r/min) |

|

|

|

|

|

|

|

|

|

| Current(A) |

0.3 |

0.72 |

0.72 |

1.25 |

1.25 |

2.4 |

2.4 |

2.4 |

4.3 |

|

| Power source | Three-phase AC 380V 50HZ,customized | |||||||||

Work Shop

Exhibition Show

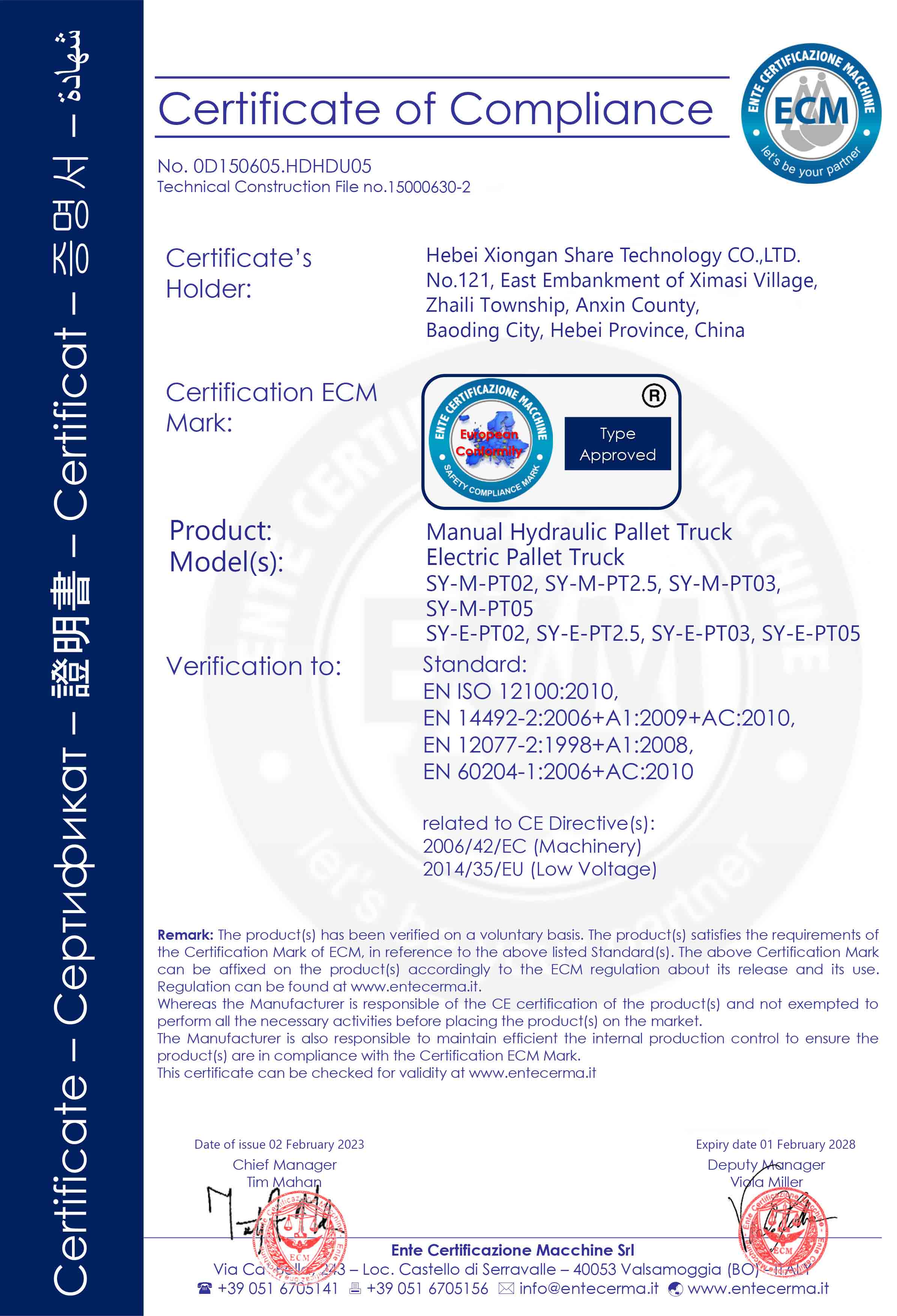

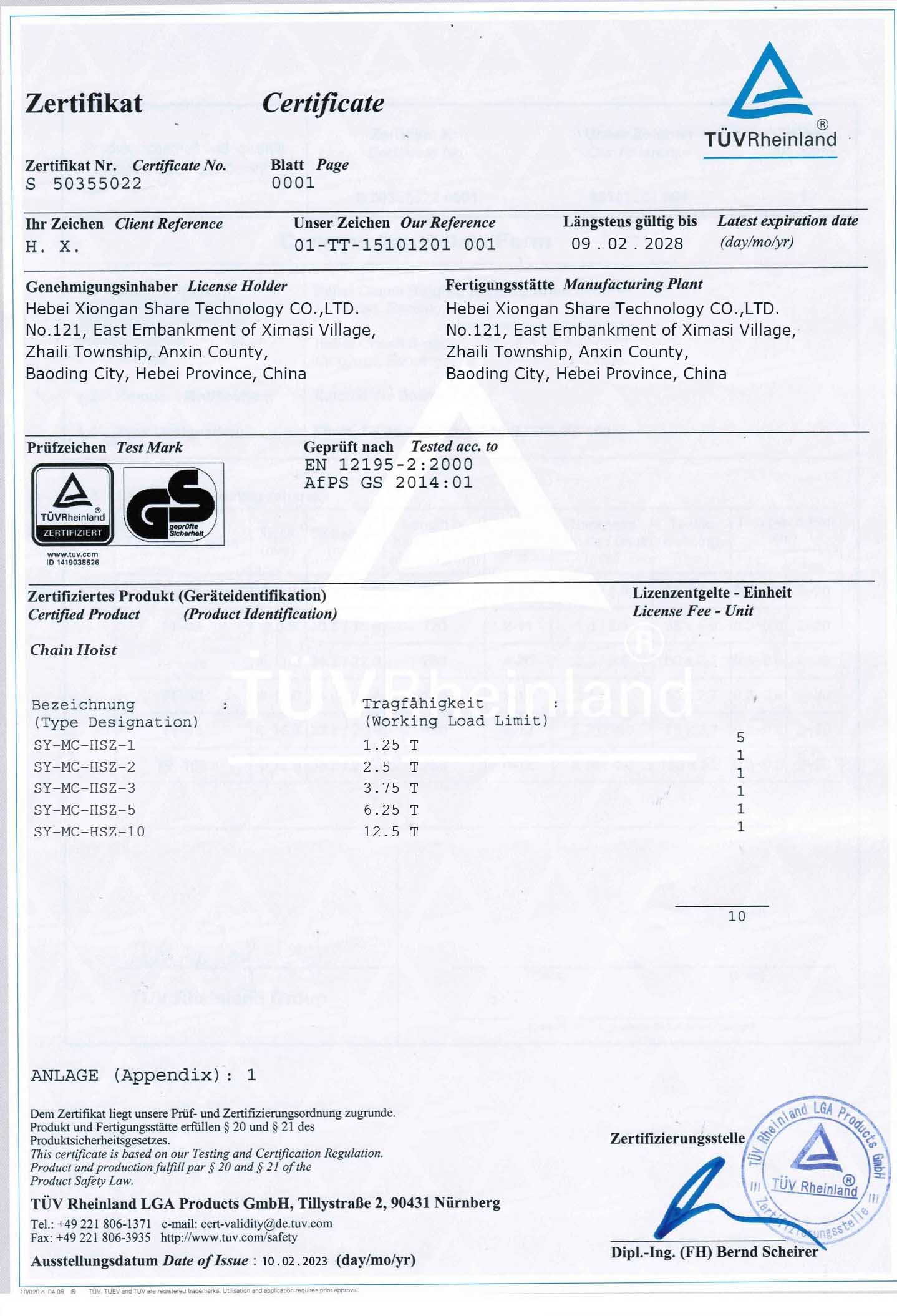

Our Certificates