Porducts

We provide a widely variety of solutions for your needs, whether you need the standard materials or special design.Manual Stacker

Application Fields

The manual hydraulic stacker (Manual Stacker) is a simple, easy-to-use and low-cost logistics equipment. Its application fields and characteristics are as follows:

Warehouses, warehouses and other logistics places: Manual hydraulic stackers are mainly used for low-height cargo stacking, handling, storage, etc., and can meet the occasions where the stacking height of goods is relatively low.

Factory and production line: The manual hydraulic stacker can be used for material transportation on the production line, and can also be used for loading, unloading, maintenance and other operations during the production process to improve production efficiency.

Shopping malls, supermarkets, logistics centers, etc.: Manual hydraulic stackers can be used for loading, unloading, transporting, placing and other operations of goods, helping shopping malls, supermarkets and other commercial places to manage goods.

Description

The stacker has simple structure, flexible operation, good micro-movement, and high explosion-proof safety performance. It is suitable for operations in narrow passages and limited spaces, and is an ideal equipment for loading and unloading pallets in high-bay warehouses and workshops. It can be widely used in petroleum, chemical, pharmaceutical, textile, military, paint, pigment, coal and other industries, as well as in ports, railways, freight yards, warehouses and other places containing explosive mixtures, for loading, unloading, stacking and handling operations. It can greatly improve work efficiency, reduce the labor intensity of workers, and win opportunities for enterprises to compete in the market

Its advantages are mainly reflected in the following aspects:

1. It integrates loading, unloading and handling, which is beneficial to reduce logistics operation links and improve loading and unloading efficiency.

2. Realize the mechanization of loading and unloading, which is conducive to reducing labor intensity, saving labor, shortening loading and unloading time, and accelerating the turnover of transport vehicles.

3. Increase the stacking height of goods and improve the utilization rate of warehouse capacity.

4. The turning radius of the forklift is small, it can turn in a narrow passage, the operation is flexible, and it can be used indoors and outdoors.

Detail Display

Detail

1. Nylon/PU wheel can be rotated for 360 degree.

2. Handle User-friendly design easy to use.

3 .Reinforced chain, more stable and durable.

4. High strength fork, high hardness and high endurance ,can be adjusted according to the size of the goods.

5. Thickened steel is strong and durable: The body is made of I-steel, and the whole body is thickened.

| Power | manual | manual | manual | manual | manual | manual | manual | |

| Unload type | hand | hand | hand | hand | hand | hand | hand | |

| Capacity | kg | 1000 | 1000 | 1000 | 1500 | 1500 | 1500 | 2000 |

| Max. lifting height | mm | 2000 | 2500 | 3000 | 2000 | 2500 | 3000 | 2000 |

| Mast | Doulbe | Doulbe | Doulbe | Doulbe | Doulbe | Doulbe | Doulbe | |

| Lowered fork height | mm | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| Fork length | mm | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 | 1150 |

| Fork width | mm | 550 | 550 | 550 | 550 | 550 | 550 | 550 |

| Front wheel size | mm | φ80*58 | φ80*58 | φ80*58 | φ80*58 | φ80*58 | φ80*58 | φ80*58 |

| Loaded wheel size | mm | φ180*50 | φ180*50 | φ180*50 | φ180*50 | φ180*50 | φ180*50 | φ180*50 |

| Overall dimension | mm | 1600*700*1580 | 1600*700*1840 | 1600*700*2080 | 1600*700*1580 | 1600*700*1840 | 1600*700*2080 | 1600*700*1580 |

| Width between legs | mm | 490 | 490 | 490 | 490 | 490 | 490 | 490 |

| Net weight | kg | 290 | 310 | 330 | 290 | 310 | 270 | 330 |

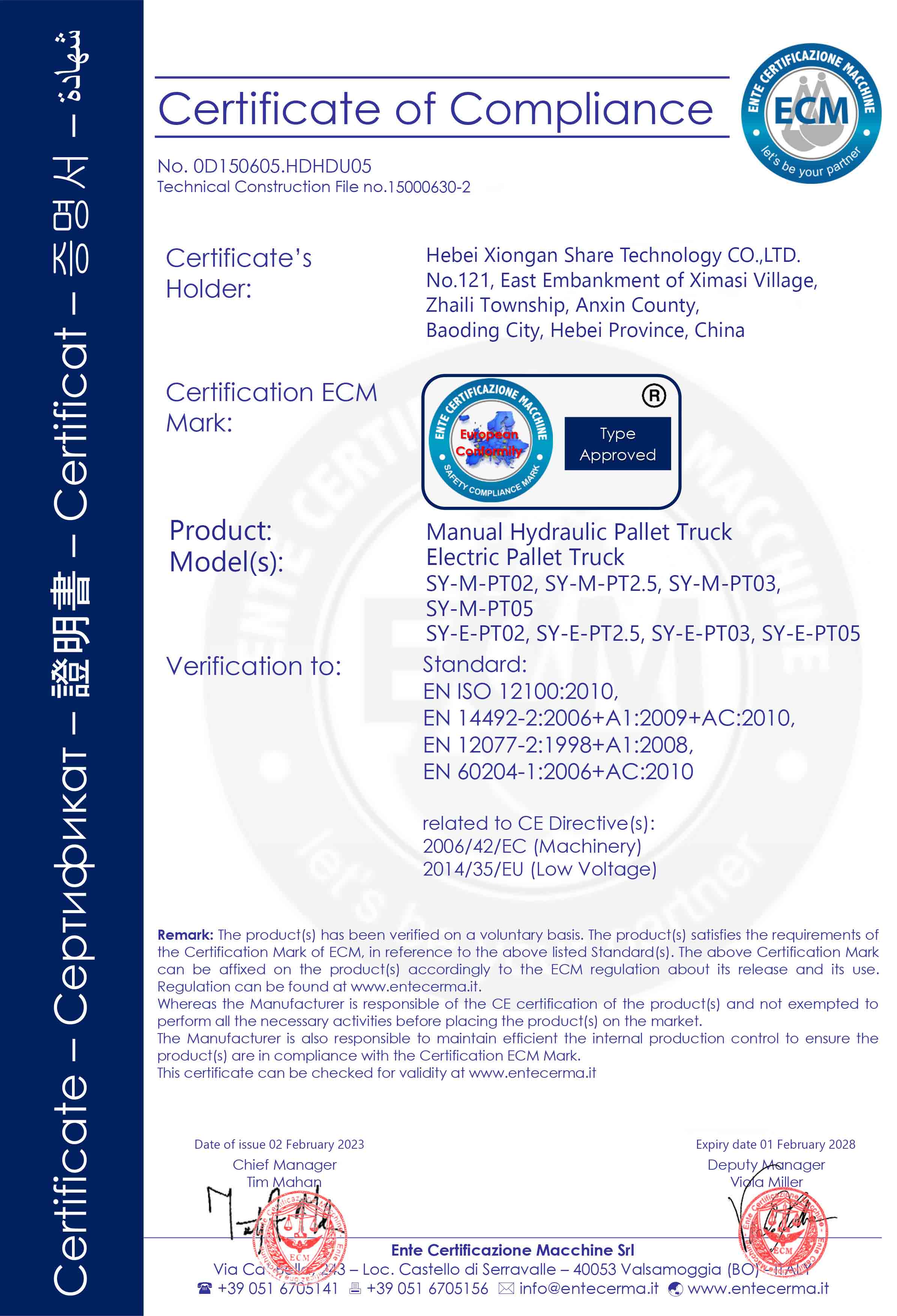

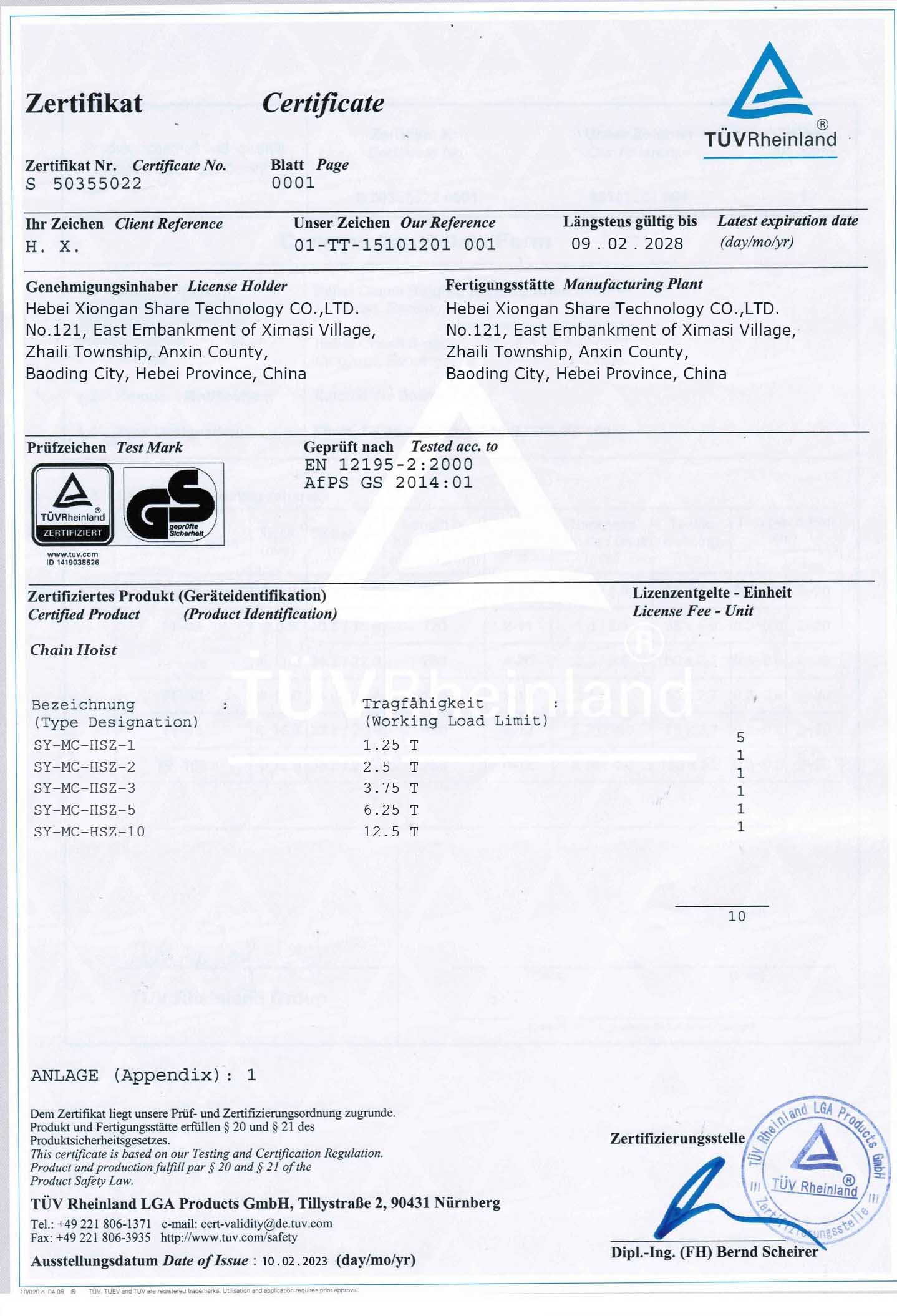

Our Certificates