Porducts

We provide a widely variety of solutions for your needs, whether you need the standard materials or special design.Micro Electric Stacker

Application Fields

Warehouses, warehouses and other logistics places: Electric stackers can be used for stacking and handling of general goods, which is convenient for improving the logistics efficiency of warehouses and warehouses.

Supermarkets, logistics centers, etc.: Electric stackers are widely used in supermarkets, warehouses, logistics centers and other fields, and can be used for loading, unloading, transshipment, and placement of goods.

Factory and production line: The electric stacker can be used for material transportation on the production line, and can also be used for loading, unloading, maintenance and other operations during the production process to improve production efficiency.

Description

Electric stacker, also known as electric stacker or electric stacker, is a kind of industrial storage equipment powered by motor and powered by battery. Its main function is to carry out operations such as stacking, unloading, and handling with pallets. It is a necessary industrial vehicle for modern factories, workshops, and warehouses. Electric pallet stacker are widely used in factories, workshops, warehouses, distribution centers and distribution centers, ports, docks, stations, airports and other places that require logistics, and can enter containers and warehouses for operation.

Electric forklifts are easy to operate and control, flexible, and the operating intensity of the operator is much lighter than that of internal combustion forklifts. The electric steering system, acceleration control system, hydraulic control system and braking system are all controlled by electrical signals, which greatly reduces It reduces the labor intensity of the operator, which is of great help to improve its work efficiency and work accuracy. And compared with internal combustion forklifts, the advantages of electric vehicles with low noise and no exhaust emissions have also been recognized by many users.

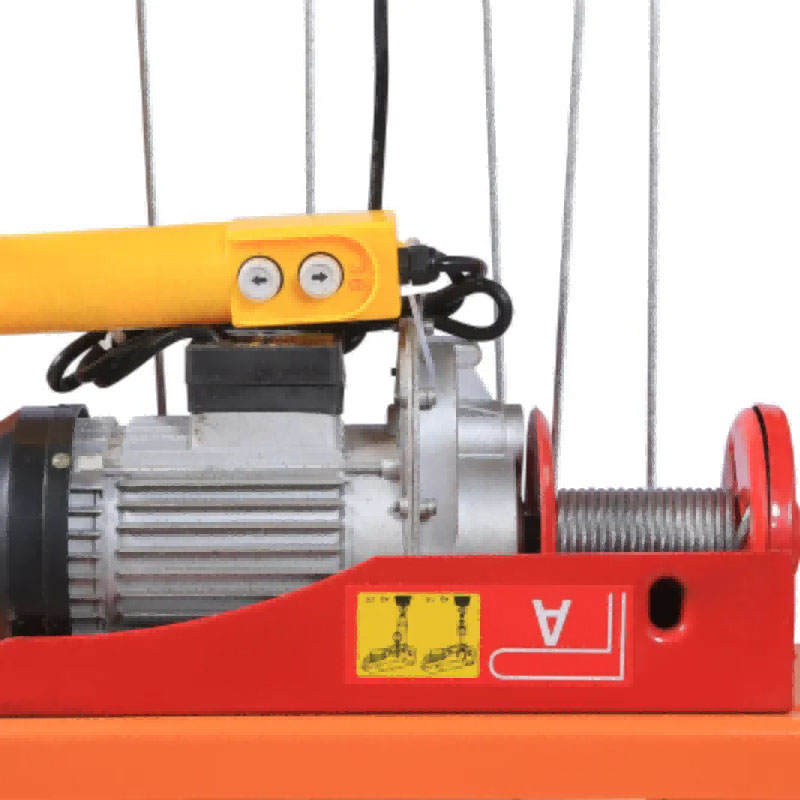

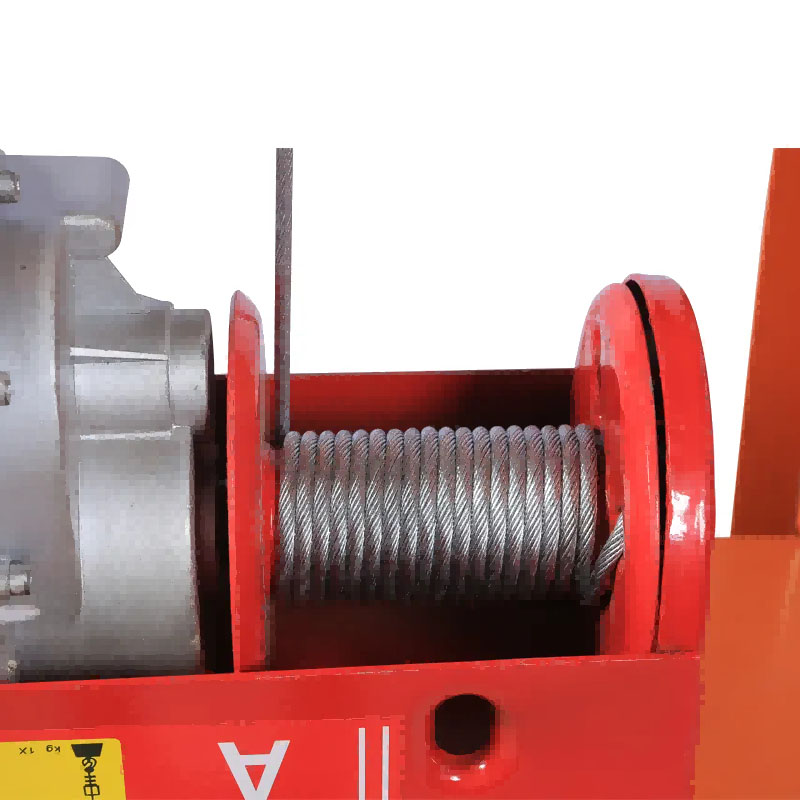

Detail Display

Detail

1. Automatic Limiter: Automatically stop when the goods reach the highest point;

2. Automatically lifting switch: Automatically power off the brake,more safer ;

3. Omni-directional wheels: Nylon/PU wheel can be rotated for 360 degree;

4. Reinforced fork:Forged manganese steel forks strong bearing capacity,suitable for various pallets;

5. Pure copper motor: Strong input power and efficient operation

6. Thickened steel is strong and durable: The body is made of I-steel, and the whole body is thickened

7. Thickened wire rope: The chain is thick, wear-resistant and durable, with strong traction;

| Model | Rated load | Lifting height | Fork length(mm) | Fork width(mm) | size(mm) | Front/ back wheel dia | NW | ||

| L | W | H | |||||||

| SY-ES-01CH | 1T | 1.6m | 840 | 100 | 1350 | 705 | 2080 | 50*90mm/50*180mm | ≈137kg |

| SY-ES-01C | 1T | 1.6m | 1000 | 140 | 1580 | 890 | 2100 | ≈167kg | |

| SY-ES-02C | 2T | 1.6m | 1000 | 140 | 1580 | 890 | 2100 | ≈190kg | |

| SY-ES-02I | 2T | 1.6m | 830 | 120 | 1410 | 702 | 2090 | ≈175kg | |

| SY-ES-03I | 3T | 1.6m | 1000 | 140 | 1250 | 800 | 2110 | ≈252.5kg | |

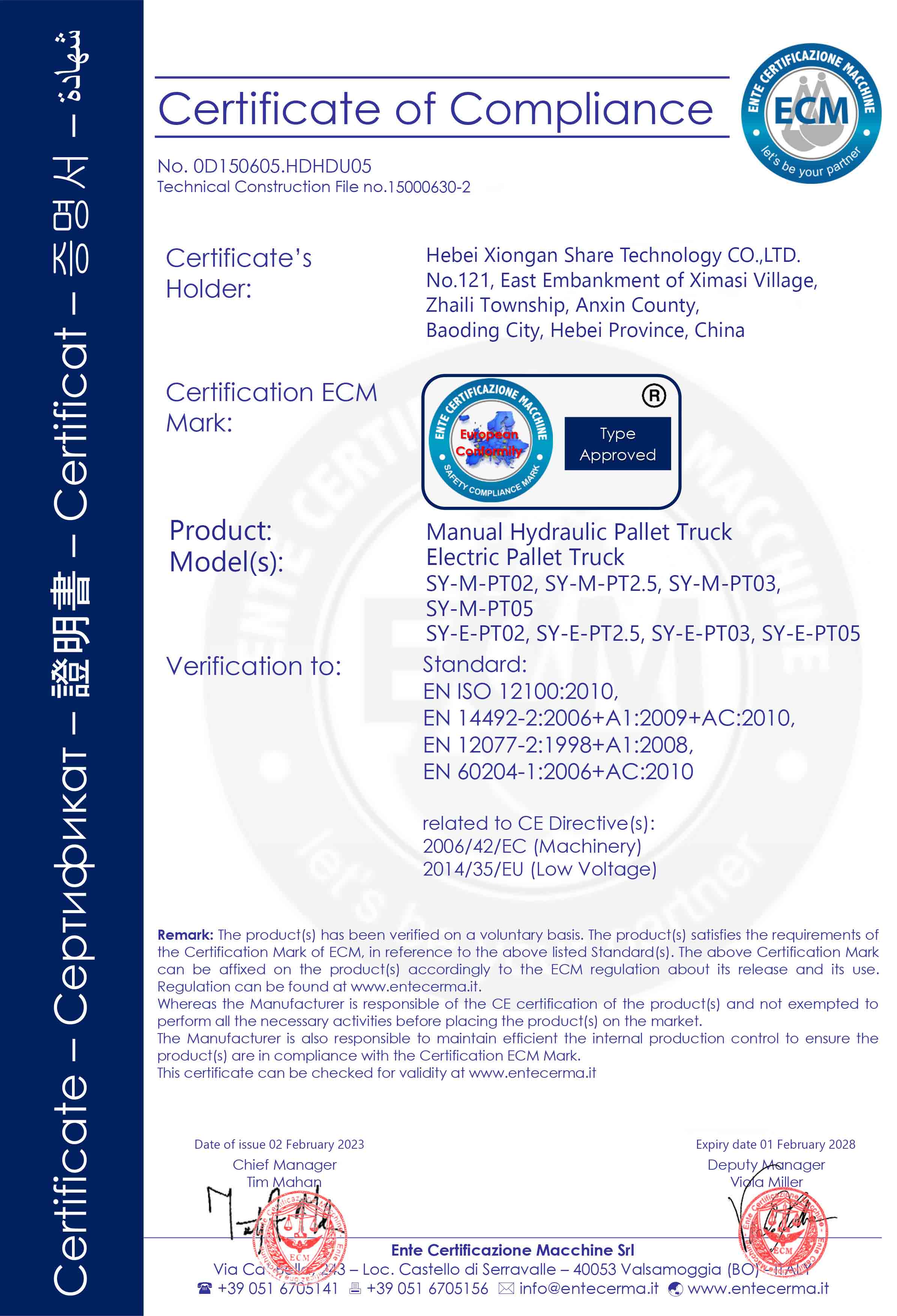

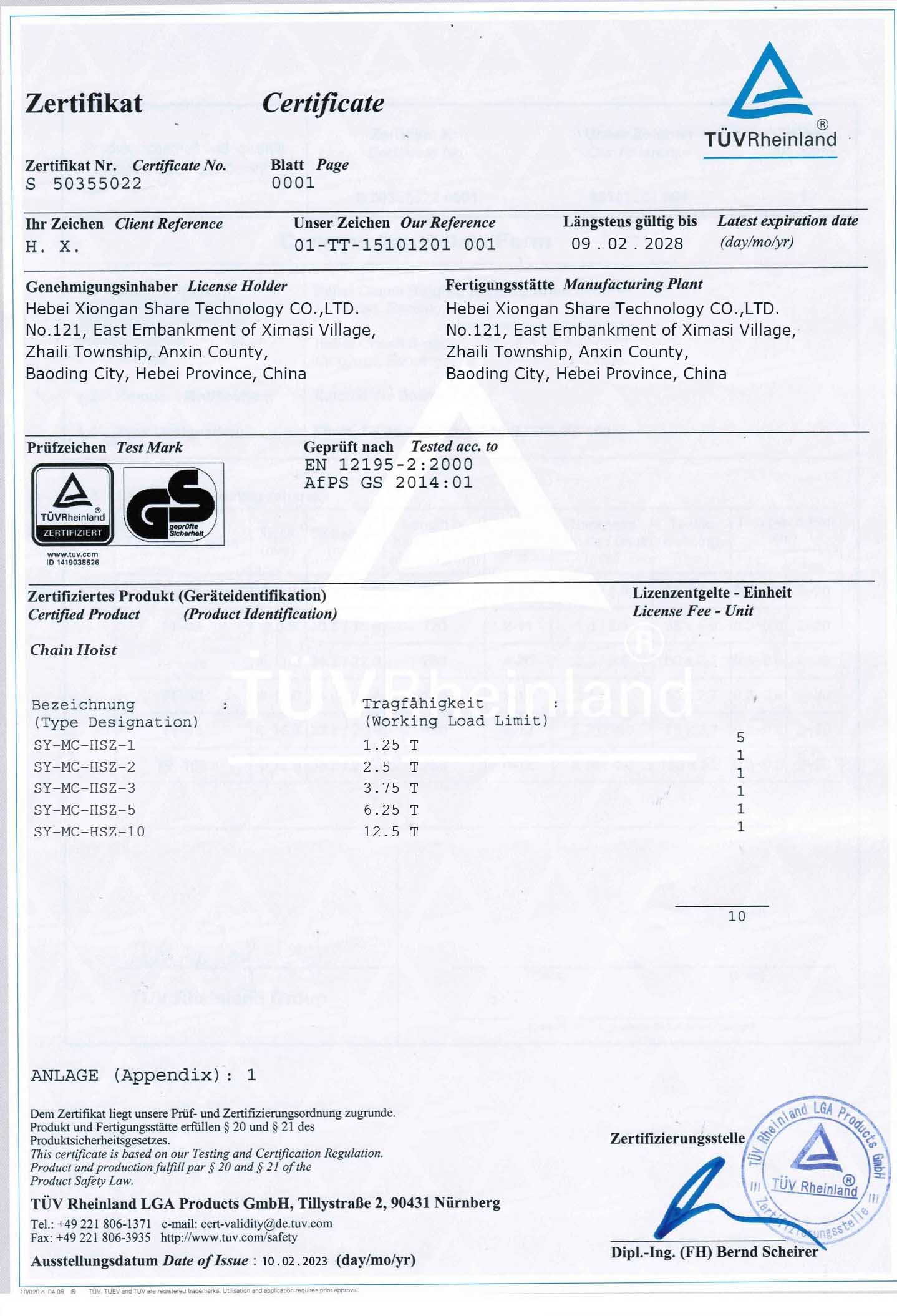

Our Certificates