Maintaining a pallet jack is essential for ensuring smooth and efficient operations in warehouses, factories, and other industrial settings. Among the critical maintenance tasks, maintaining the proper oil level is paramount. In this comprehensive guide, we'll delve deeper into the importance of oil maintenance for pallet jacks and provide detailed steps on how to refill the oil to keep your equipment in top condition.

Importance of Oil Maintenance:

1. Smooth Operations:The hydraulic system of a pallet jack relies on oil to function properly. Adequate oil levels ensure smooth and effortless lifting and lowering of the forks, contributing to increased productivity and efficiency in material handling tasks.

2. Prevention of Damage: Insufficient oil levels can lead to increased friction and wear within the hydraulic system components, potentially causing damage or premature failure. Regular oil maintenance helps prevent costly repairs and downtime.

3. Safety: Properly maintained pallet jacks are safer to operate. Ensuring the correct oil level reduces the risk of malfunction or unexpected failures that could pose safety hazards to operators and nearby personnel.

4.Longevity: Well-maintained pallet jacks have a longer service life. By regularly checking and topping up the oil, you can extend the lifespan of your equipment and maximize its return on investment.

Step-by-Step Guide to Refilling Pallet Jack Oil:

1. Gather the Necessary Equipment:

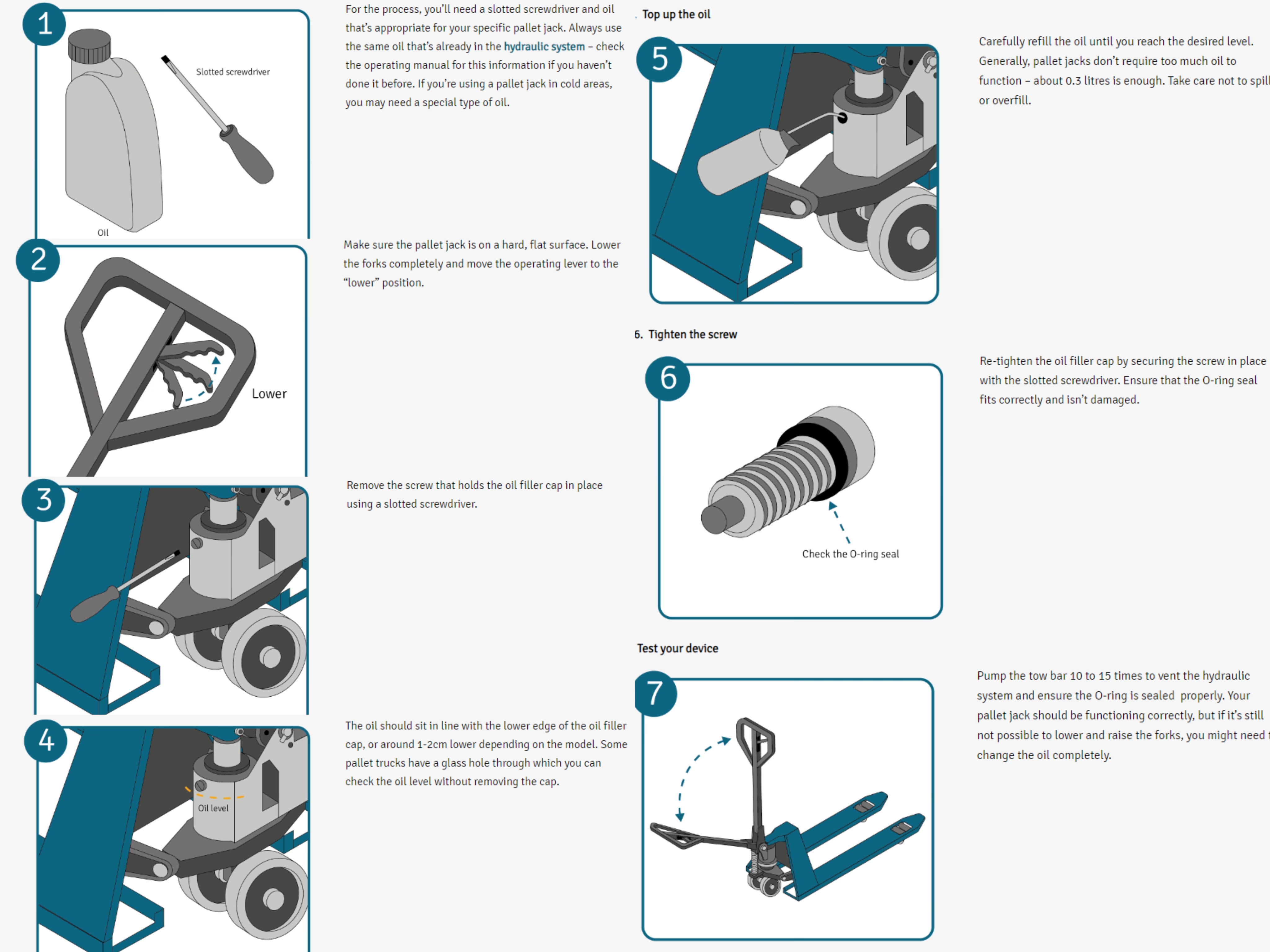

Before starting the oil refill process, ensure you have the required tools and materials on hand. You'll need a slotted screwdriver and oil suitable for your pallet jack. Refer to the operating manual to determine the appropriate oil type for your specific model.

2. Prepare the Pallet Jack:

Position the pallet jack on a hard, flat surface to ensure stability during the maintenance process. Lower the forks completely and set the operating lever to the "lower" position to release any pressure in the hydraulic system.

3. Access the Oil Filler Cap:

Use a slotted screwdriver to remove the screw holding the oil filler cap in place. Carefully lift off the cap to access the oil reservoir.

4. Check the Oil Level:

With the oil filler cap removed, visually inspect the oil level in the reservoir. The oil should ideally be in line with the lower edge of the filler cap or approximately 1-2cm below, depending on the pallet jack model. Some pallet jacks may have a transparent window for easy oil level checking.

5. Top Up the Oil:

If the oil level is below the recommended range, carefully pour in the appropriate amount of oil to reach the desired level. Avoid overfilling the reservoir, as this can lead to excessive pressure and potential damage to the hydraulic system. Typically, adding around 0.3 litres of oil is sufficient for most pallet jacks.

6. Secure the Oil Filler Cap:

Once the oil has been topped up, reposition the oil filler cap onto the reservoir and secure it in place by tightening the screw with the slotted screwdriver. Ensure that the O-ring seal is correctly positioned and undamaged to prevent oil leaks.

7. Test the Pallet Jack:

To ensure proper sealing and functionality of the hydraulic system, pump the tow bar 10 to 15 times to vent any trapped air and distribute the oil evenly. Test the pallet jack by lowering and raising the forks multiple times to verify smooth operation.

By following these steps and incorporating regular oil maintenance into your pallet jack maintenance routine, you can ensure optimal performance, longevity, and safety of your equipment. Remember to schedule periodic checks and oil top-ups as needed to keep your pallet jack in peak condition for years to come.

Adding a Personal Experience:

In addition to the comprehensive guide on pallet jack oil maintenance, I'd like to share a personal experience highlighting the importance of diligent upkeep.

Last year, while overseeing warehouse operations, I encountered a situation where one of our pallet jacks started experiencing difficulty in lifting heavy loads. Initially, we suspected a mechanical issue and called in a technician for inspection. However, upon closer examination, we discovered that the oil level in the hydraulic system was significantly low.

Reflecting on this incident, I realized that we had overlooked the importance of regular oil maintenance. Despite having a maintenance schedule in place, it was easy to miss subtle signs of oil depletion, especially during busy periods. This oversight not only led to unexpected downtime but also incurred additional repair costs that could have been avoided with proper maintenance.

This experience served as a valuable lesson for our team, emphasizing the critical role of proactive maintenance practices. Since then, we've implemented stricter oil maintenance protocols, including regular oil level checks and scheduled top-ups. By staying vigilant and proactive, we've been able to prevent similar incidents and ensure uninterrupted operations in our facility.

By sharing this personal anecdote, I hope to underscore the significance of oil maintenance and inspire others to prioritize this essential aspect of pallet jack care. Through diligence and attention to detail, we can mitigate risks, prolong equipment lifespan, and maintain a safe and efficient work environment.

Post time: Mar-27-2024