Porducts

We provide a widely variety of solutions for your needs, whether you need the standard materials or special design.Pneumatic Hoist

Long Description

Key Features of Air Hoists:

Compressed Air Power: Pneumatic Hoist are powered by compressed air, which is a clean and abundant energy source. This power method provides consistent and reliable performance, making air hoists ideal for heavy lifting tasks.

Precise Control: Air hoists offer precise load control, allowing operators to lift, lower, and position loads with accuracy. This precision is crucial, especially in industries where safety and delicate handling are paramount.

Variable Speed: Many air hoists are designed with variable speed controls, enabling operators to adjust lifting and lowering speeds according to the specific requirements of the task. This feature enhances flexibility and efficiency.

Durability: Pneumatic Hoist are renowned for their robust construction and resistance to harsh working conditions. They are often used in demanding environments such as foundries, shipyards, and construction sites.

Overload Protection: Modern Pneumatic Hoist are equipped with safety features like overload protection to prevent accidents caused by excessive loads. These safety mechanisms enhance workplace safety.

Compact Design: Pneumatic Hoist typically have a compact and lightweight design, making them easy to install and maneuver in tight spaces. This versatility suits a wide range of applications.

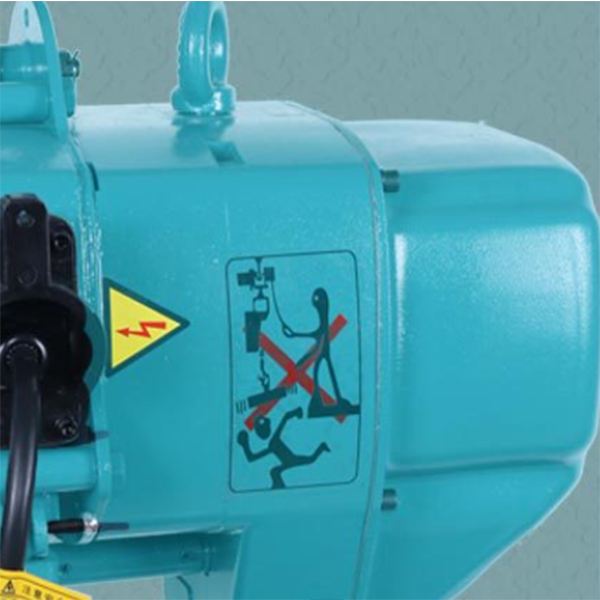

Detail Display

Detail

1.Durable shell for protection:

Quick adjustment of the position of thechain with quick adjustment of the handwheelweston ratchet pawl load protection device;

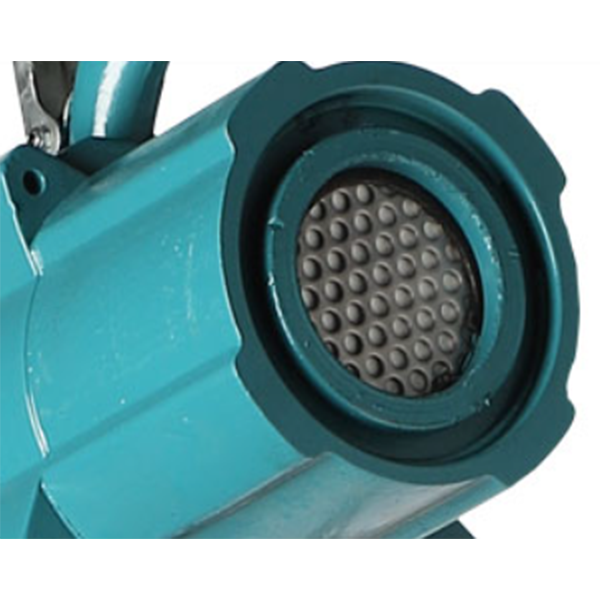

2.Cast Steel Gear:

Made of alloy steel by carb-urizingquenching treatmentLow noise and high efficiency;

3.G80 grade manganese steel chair:

Not easily deformedHigh strength and great intensity,more safety;

4.The hook of manganese steel:

Made of alloy steel by carb-urizingquenching treatmentLow noise and high efficiency;

|

Model |

unit |

3TI |

5TI |

6TI |

8TI |

10TI |

||||||

|

pressure |

bar |

3.2 |

5 |

6.3 |

8 |

10 |

||||||

|

Enhance ability |

t |

4 |

6 |

4 |

6 |

4 |

6 |

4 |

6 |

4 |

||

|

Number of chains |

|

1 |

2 |

2 |

2 |

2 |

||||||

|

Motor output power |

kw |

1.8 |

3.5 |

1.8 |

3.5 |

1.8 |

3.5 |

1.8 |

3.5 |

1.8 |

||

|

Full load lifting speed |

m/min |

2.5 |

5 |

1.2 |

2.5 |

1.2 |

2.5 |

0.8 |

1.6 |

0.8 |

||

|

Empty lifting speed |

m/min |

6 |

10 |

3 |

5 |

3 |

5 |

2 |

3.2 |

2 |

||

|

Full load descent speed |

m/min |

7.5 |

10.8 |

3.6 |

5.4 |

3.6 |

5.4 |

2.5 |

3.4 |

2.5 |

||

|

Full load gas consumption - during lifting |

m/min |

2 |

4 |

2 |

4 |

2 |

4 |

2 |

4 |

2 |

||

|

Full load gas consumption - during descent |

m/min |

3.5 |

5.5 |

3.5 |

5.5 |

3.5 |

5.5 |

3.5 |

5.5 |

3.5 |

||

|

Tracheal joint |

|

G3/4 |

||||||||||

|

Pipeline size |

mm |

19 |

||||||||||

|

Standard lift and weight within the length range |

mm |

86 |

110 |

110 |

156 |

156 |

||||||

|

Chain size |

mm |

13X36 |

13X36 |

13X36 |

16X48 |

16X48 |

||||||

|

Chain weight per meter |

kg |

3.8 |

3.8 |

3.8 |

6 |

6 |

||||||

|

Lifting height |

m |

3 |

||||||||||

|

Standard controller pipeline length |

m |

2 |

||||||||||

|

Full load noise with silencer - increase by 1 |

decibel |

74 |

78 |

74 |

78 |

74 |

78 |

74 |

78 |

74 |

||

|

Full load noise with silencer - decrease by 1 |

decibel |

79 |

80 |

79 |

80 |

79 |

80 |

79 |

80 |

79 |

||

|

|

|

3TI |

5TI |

6TI |

8TI |

10TI |

15TI |

16TI |

20TI |

|

||

|

A minimum clearance 1 |

mm |

593 |

674 |

674 |

674 |

813 |

898 |

898 |

1030 |

|

||

|

B |

mm |

373 |

454 |

454 |

454 |

548 |

598 |

598 |

670 |

|

||

|

C |

mm |

233 |

233 |

233 |

308 |

308 |

382 |

382 |

382 |

|

||

|

D |

mm |

483 |

483 |

483 |

483 |

575 |

682 |

682 |

692 |

|

||

|

E1 |

mm |

40 |

40 |

40 |

40 |

44 |

53 |

53 |

75 |

|

||

|

E2 |

mm |

30 |

40 |

40 |

40 |

44 |

53 |

53 |

75 |

|

||

|

F to the center of the hook |

mm |

154 |

187 |

187 |

197 |

197 |

219 |

219 |

235 |

|

||

|

G maximum width |

mm |

233 |

233 |

233 |

233 |

306 |

308 |

308 |

315 |

|||

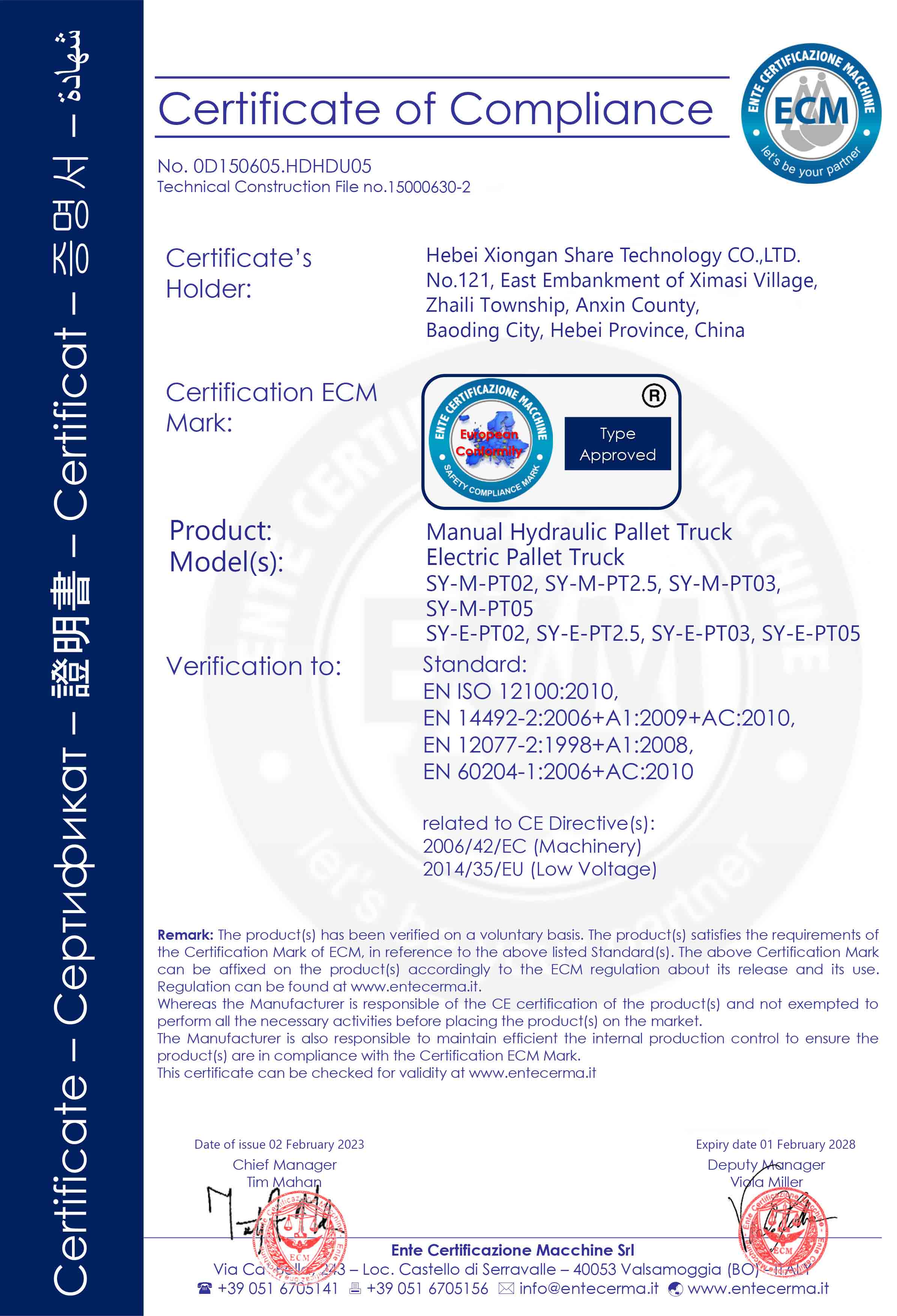

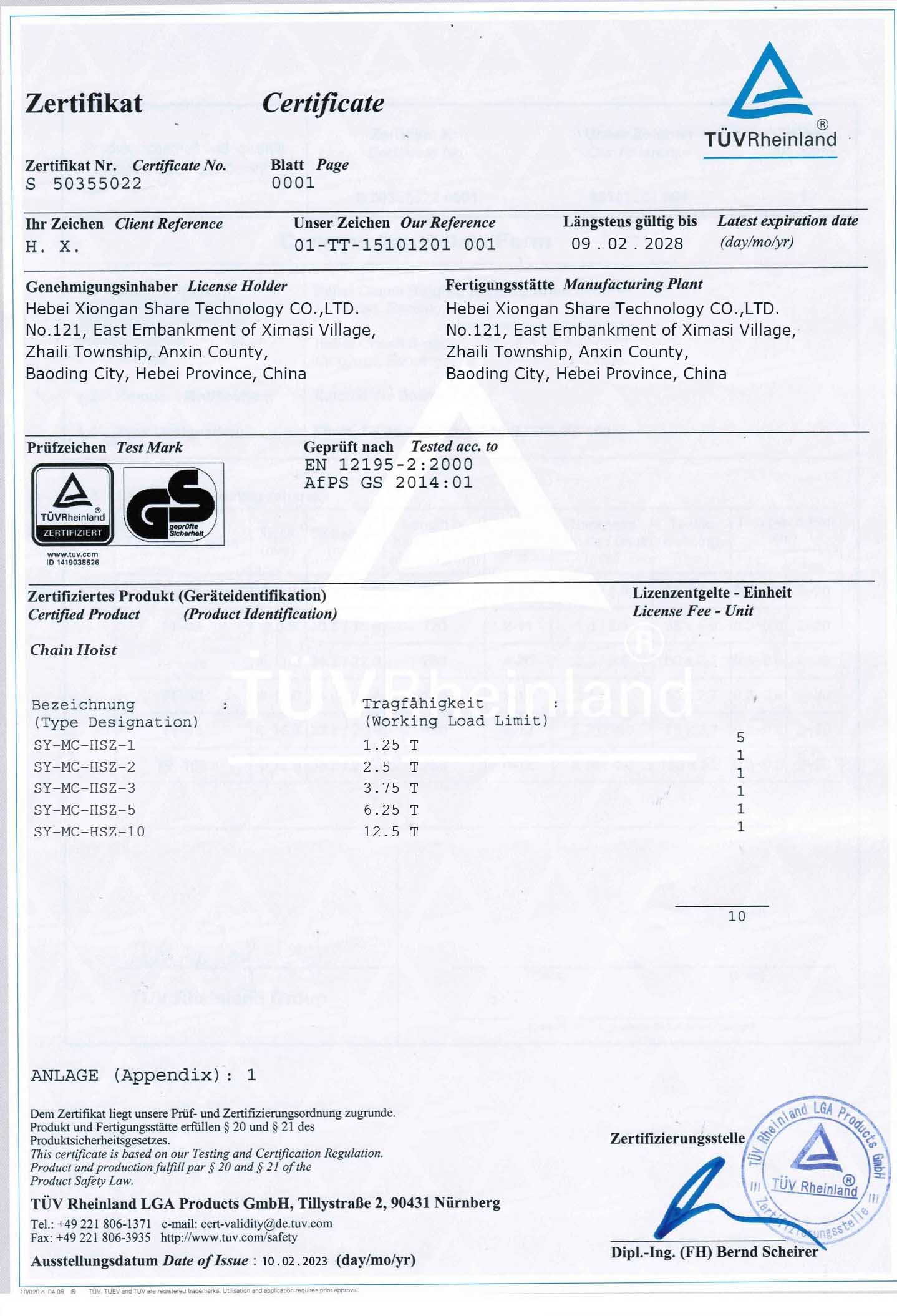

Our Certificates