Porducts

We provide a widely variety of solutions for your needs, whether you need the standard materials or special design.Wholesale Galvanized Screw Type D Shackles for lifting

Application Fields

Screw type D shackles are commonly used in various industries for different lifting and rigging applications such as:

Marine industry: For securing and lifting heavy items like anchors, chains, and ropes.

Construction industry: Used in cranes, excavators, and other heavy machinery for lifting and hoisting construction materials like steel beams, pipes, and concrete blocks.

Offshore and oil fields: Used for lifting and securing pipelines, drilling equipment, and heavy machinery.

Rigging industry: Used for suspending loads and lifting heavy items in theatrical productions, concerts, and other entertainment events.

Short Introduction

The operating rod is also an important part of the shackle. The operating rod can be attached to the shackle to provide better control and operation. The length and shape of the levers vary for different purposes, for example, when dismantling various parts and accessories of an aircraft, the levers can be used to securely place the shackle and to make the removal work easier and more precise.

In conclusion, the shackle is a very practical tool that can help workers, engineers and mechanics to quickly open and connect chains or ropes, so as to strengthen and strengthen various types of structures, and improve the efficiency and safety of work.

Detail Display

Description

A shackle is a type of rigging. Shackles commonly used in the domestic market are generally divided into three types according to production standards: national standard, American standard, and Japanese standard; among them, the American standard is the most commonly used, and is widely used because of its small size and large load capacity. According to the type, it can be divided into G209 (BW), G210 (DW), G2130 (BX), G2150 (DX). According to the type, it can be divided into bow type (Omega shape) bow type with female shackle and D type (U type or straight Type) D type with female shackle; according to the place of use, it can be divided into two types: marine and land. The safety factor is 4 times, 5 times, 6 times, or even 8 times (such as the Swedish GUNNEBO super shackle). Its materials are common carbon steel, alloy steel, stainless steel, high-strength steel, etc. Surface treatment is generally divided into galvanizing (hot dipping and electroplating), painting, and Dacromet plating. The rated load of the shackle: the common American standard shackle specifications in the market are 0.33T, 0.5T, 0.75T, 1T, 1.5T, 2T, 3.25T, 4.75T, 6.5T, 8.5T, 9.5T, 12T, 13.5T , 17T, 25T, 35T, 55T, 85T, 120T, 150T.

Detail

1. Selected Material: Strict selection of raw materials,layers of screening, production and processing in accordance with relevant standards.

2. Surface: smooth surface without burr deep hole thread, sharp screw teeth;

| It em No. | Weight/lbs | WLL/T | BF/T |

| 1/4 | 0.13 | 0.5 | 2 |

| 5/16 | 0.23 | 0.75 | 3 |

| 3/8 | 0.33 | 1 | 4 |

| 7/16 | 0.49 | 1.5 | 6 |

| 1/2 | 0.75 | 2 | 8 |

| 5/8 | 1.47 | 3.25 | 13 |

| 3/4 | 2.52 | 4.75 | 19 |

| 7/8 | 3.85 | 6.5 | 26 |

| 1 | 5.55 | 8.5 | 34 |

| 1-1/8 | 7.6 | 9.5 | 38 |

| 1-1/4 | 10.81 | 12 | 48 |

| 1-3/8 | 13.75 | 13.5 | 54 |

| 1-1/2 | 18.5 | 17 | 68 |

| 1-3/4 | 31.4 | 25 | 100 |

| 2 | 46.75 | 35 | 140 |

| 2-1/2 | 85 | 55 | 220 |

| 3 | 124.25 | 85 | 340 |

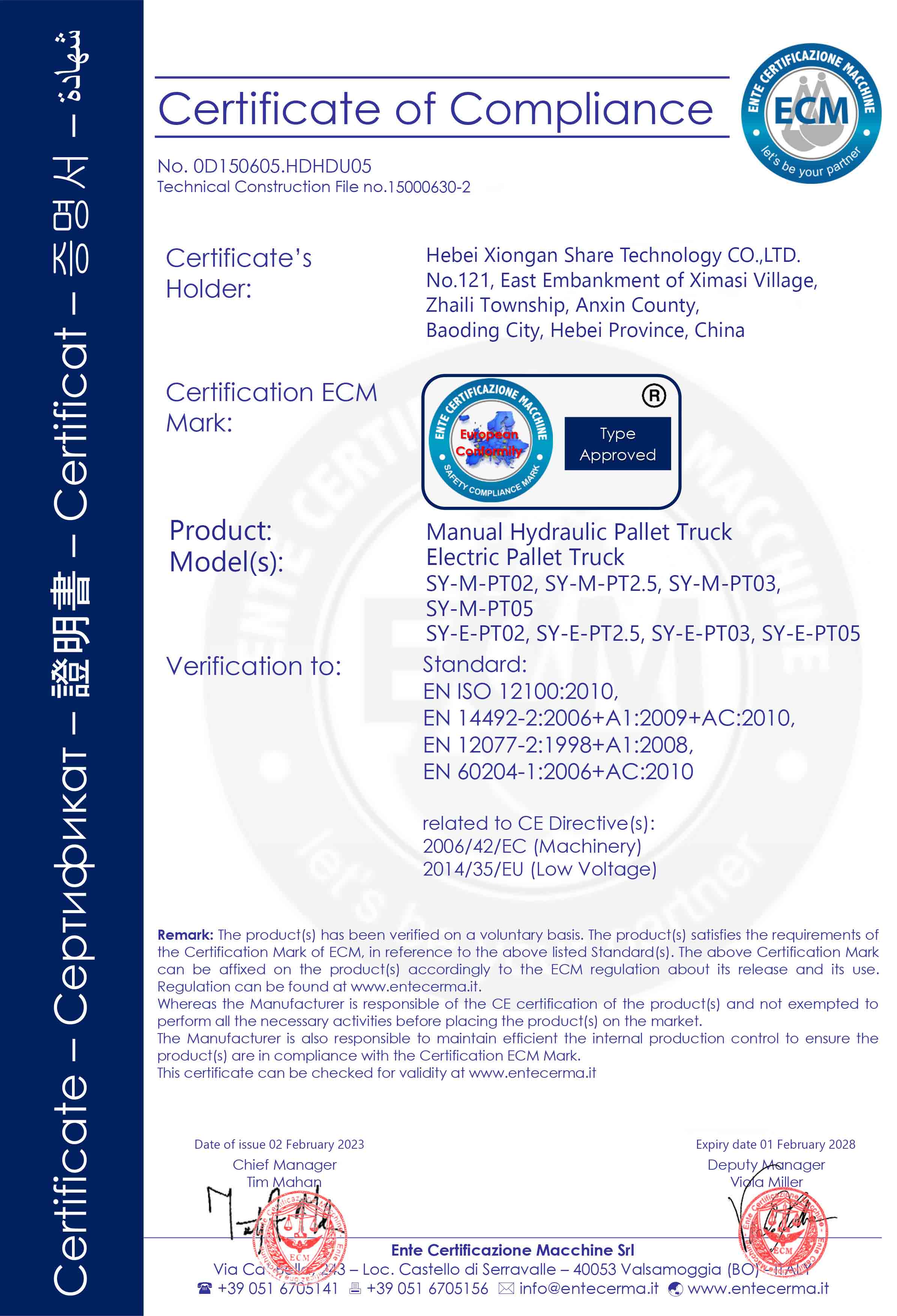

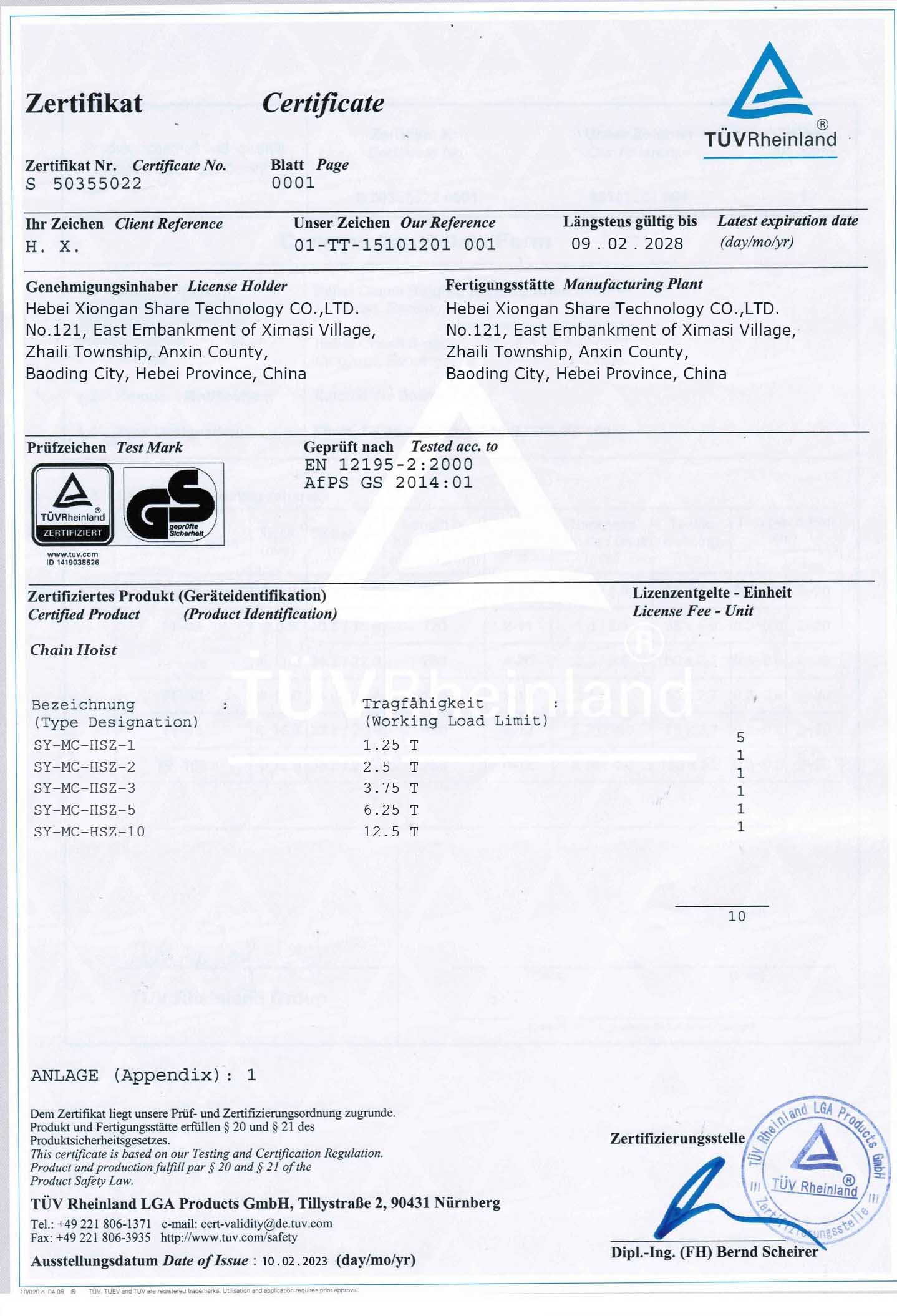

Our Certificates